دستگاه حلقه خم کننده میله فولادی, دستگاه حلقه آهنی تخت, دستگاه یکپارچه خم و برش میله فولادی

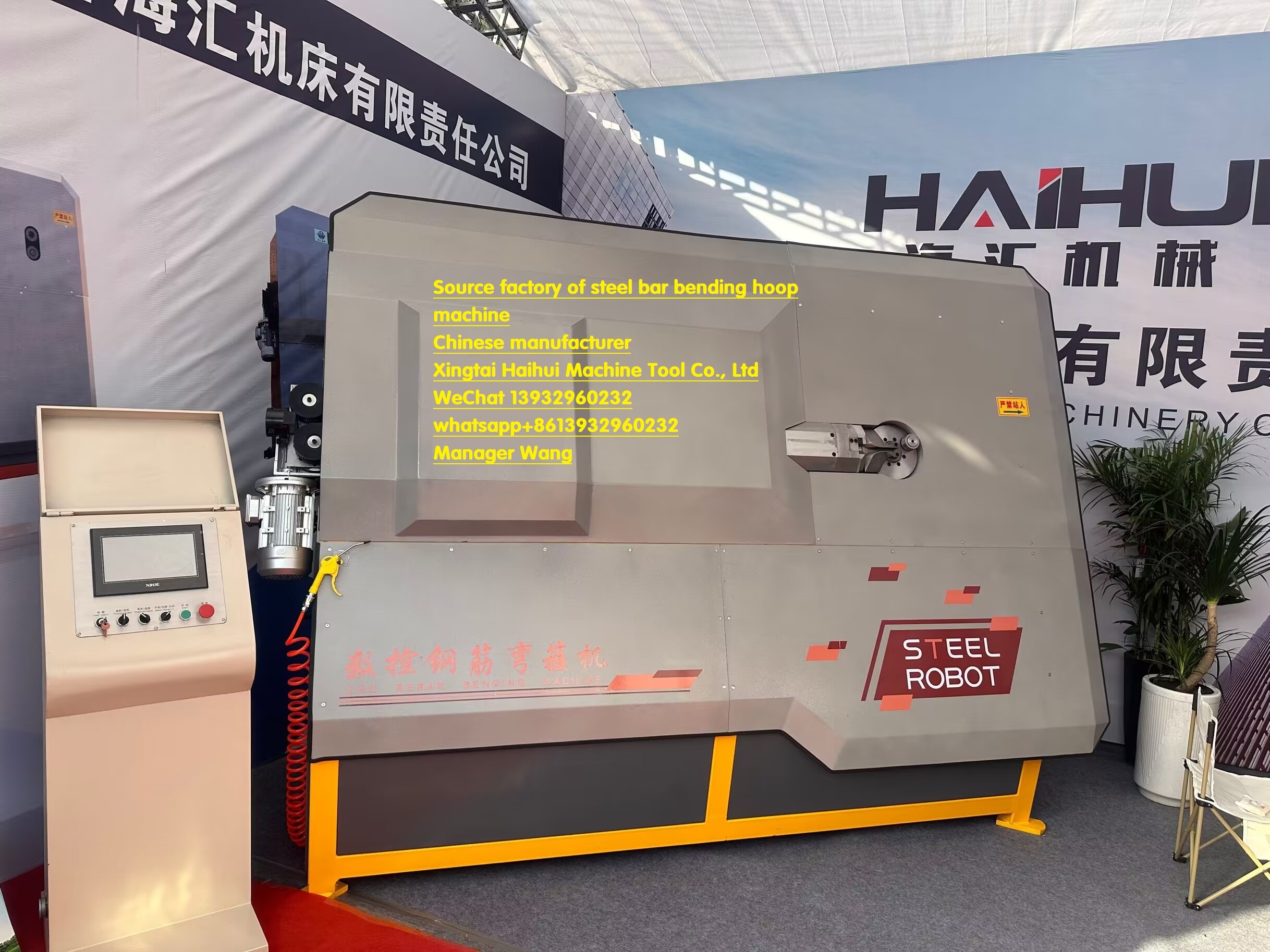

Steel Bar Bending Hoop Machine, Flat Iron Hoop Machine, Steel Bar Bending and Cutting Integrated Machine: A Comprehensive Overview

In the construction and metal processing industries, the steel bar bending hoop machine, دستگاه حلقه آهنی تخت, and steel bar bending and cutting integrated machine play crucial roles. These machines have revolutionized the way steel components are fabricated, offering efficiency, دقت, and versatility.

Steel Bar Bending Hoop Machine

The steel bar bending hoop machine is primarily designed to bend steel bars into hoop shapes with high accuracy. It is widely used in construction projects for the production of reinforced concrete structures.

- Working Principle: Most steel bar bending hoop machines operate through a combination of mechanical and electrical systems. They use motors and gears to drive the bending mechanism. The steel bar is fed into the machine, and the bending head rotates or moves to bend the bar at the desired angle and radius. Some advanced models are equipped with CNC (Computer Numerical Control) systems, allowing for precise programming of bending parameters such as angle, قطر, and pitch.

- Advantages

- High Precision: It can achieve accurate bending angles, usually within a very small tolerance range, ensuring the uniformity and quality of the hoops. This is crucial for the structural integrity of reinforced concrete.

- High Efficiency: Significantly faster than manual bending, it can produce a large number of hoops in a short time, increasing construction productivity.

- Versatility: Can handle different diameters of steel bars, typically ranging from 6mm to 42mm, depending on the machine model. It can also bend bars made of various materials such as carbon steel and stainless steel.

Flat Iron Hoop Machine

The flat iron hoop machine is specialized in bending flat iron strips into hoop or ring shapes. It is commonly used in industries like furniture manufacturing, decoration, and pipeline installation.

- Working Principle: Similar to the steel bar bending hoop machine, the flat iron hoop machine uses a bending mechanism. هر چند, it is designed to handle flat iron materials. The machine may have adjustable rollers or bending dies to accommodate different widths and thicknesses of the flat iron. Some flat iron hoop machines also incorporate a cutting function to trim the flat iron to the required length before or after bending.

- Advantages

- Customization: Allows for the production of hoops with different sizes and shapes, meeting specific project requirements. The adjustable components enable easy customization of the bending radius and angle.

- Smooth Bending: Ensures a smooth and even bend on the flat iron, minimizing the risk of cracks or deformations. This is important for maintaining the aesthetic and functional quality of the hoops.

- Wide Application: Suitable for a variety of applications. In the furniture industry, it is used to make decorative elements and structural supports. In the pipeline industry, it is used to produce pipe clamps and supports.

Steel Bar Bending and Cutting Integrated Machine

The steel bar bending and cutting integrated machine combines the functions of both bending and cutting steel bars, offering a one-stop solution for steel bar processing.

- Working Principle: This machine integrates a bending unit and a cutting unit. The steel bar is first fed into the machine, and the cutting unit cuts the bar to the desired length. Then, the bending unit takes over and bends the cut bar into the required shape. The whole process is coordinated by a control system, which can be either manual or automated, depending on the machine’s sophistication.

- Advantages

- Time and Cost Saving: Eliminates the need for separate cutting and bending machines, reducing equipment investment and floor space. It also saves time by performing both operations in one continuous process, improving overall processing efficiency.

- High Accuracy: The integrated control system ensures that the cutting and bending operations are precisely coordinated. This results in accurate lengths and bending angles, reducing material waste and improving the quality of the final products.

- انعطاف پذیری: Can handle a wide range of steel bar sizes and shapes. It can be programmed to produce different types of bent and cut steel bars, making it suitable for various construction and metalworking projects.

در نتیجه, the steel bar bending hoop machine, دستگاه حلقه آهنی تخت, and steel bar bending and cutting integrated machine are essential tools in the construction and metal processing fields. They offer efficiency, دقت, and versatility, enabling manufacturers and construction companies to produce high-quality steel components with ease. Whether it’s for building structures, furniture making, or pipeline installation, these machines play a vital role in enhancing productivity and ensuring the success of projects.