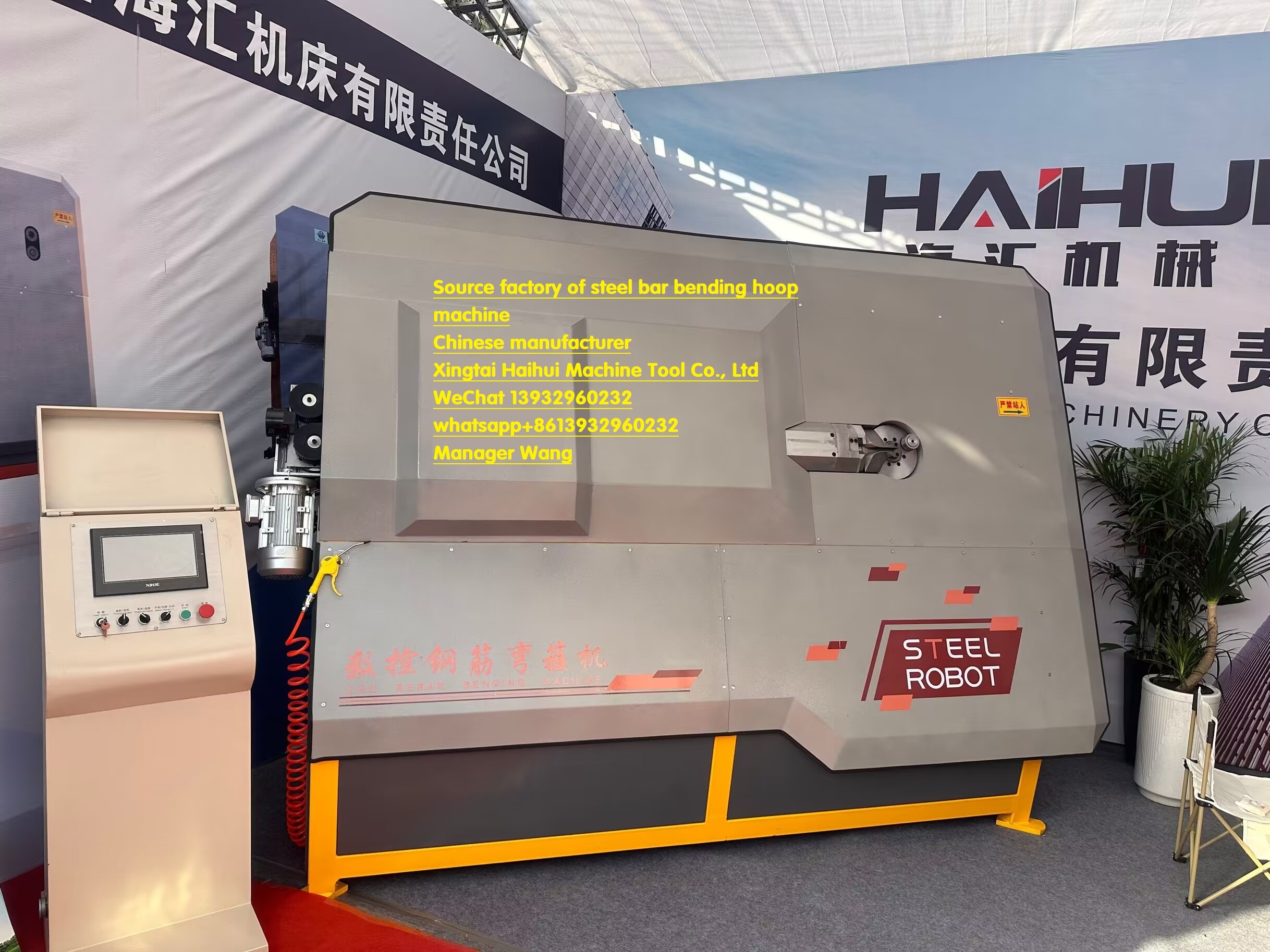

Na agitação dos canteiros de obras e oficinas de metalurgia, a introdução da máquina integrada de endireitamento e dobramento do bastidor foi uma virada de jogo. Este notável equipamento transformou a forma como as tarefas são realizadas, tornando o trabalho uma brisa.

Já se foram os dias de luta com máquinas separadas para endireitar e dobrar aros. The integrated machine streamlines the entire process, eliminating the need for multiple setups and reducing the time and effort spent on each operation.

With its advanced technology and user-friendly design, even complex tasks become effortless. The machine’s precision and efficiency ensure that the materials are processed accurately and quickly, minimizing errors and rework.

Operators no longer have to endure the physical strain of handling heavy materials and performing repetitive motions. The integrated machine does the heavy lifting, allowing workers to focus on other aspects of the project with ease.

It not only simplifies the workflow but also enhances productivity and output. Faster completion of tasks leads to increased project turnaround times and greater customer satisfaction.

In essence, the straightening and bending hoop integrated machine has become an indispensable asset, making work not only easier but also more enjoyable and efficient. It is a true testament to how innovation can revolutionize an industry and improve the working experience for all involved.