Trong thế giới xây dựng và sản xuất hiện đại, vai trò của một nhà sản xuất máy uốn thanh thép hoàn toàn tự động là không thể thiếu. Những nhà sản xuất này là bậc thầy về nghệ thuật kết hợp công nghệ và tay nghề để tạo ra các giải pháp uốn thép chính xác và đáng tin cậy.

The manufacturing process begins with a deep understanding of the requirements of various industries. The manufacturer studies the diverse needs of construction, infrastructure, and engineering projects to design machines that can meet the specific demands of each application.

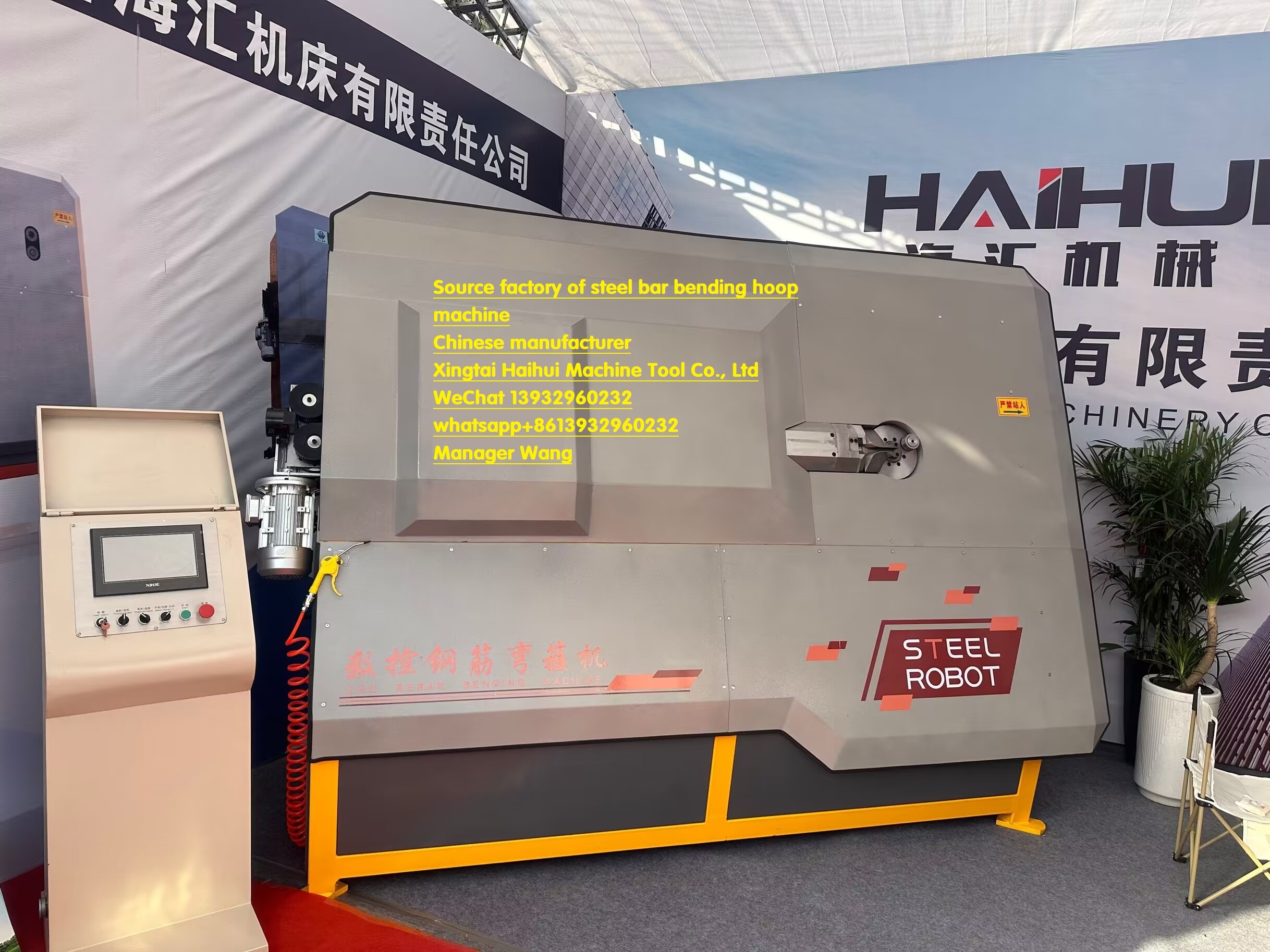

The heart of their operation lies in the exquisite craftsmanship. Skilled technicians and engineers employ state-of-the-art tools and techniques to assemble and calibrate each component of the machine with utmost precision. Every part is crafted to perfection, ensuring seamless operation and consistent performance.

The materials used are of the highest quality, selected for their durability and strength. This ensures that the machines can withstand the rigors of continuous use and handle even the toughest steel bars with ease.

Advanced control systems are integrated to provide operators with precise control over the bending process. These systems allow for adjustments in angles, lengths, and speeds, enabling the creation of complex and accurate bends.

The manufacturer also places a strong emphasis on safety. The machines are designed with multiple safety features to protect operators and prevent accidents.

Tóm lại, a fully automatic steel bar bending machine manufacturer is not just a producer of machinery but a creator of solutions that shape the future of construction and manufacturing through their exquisite craftsmanship and dedication to quality.